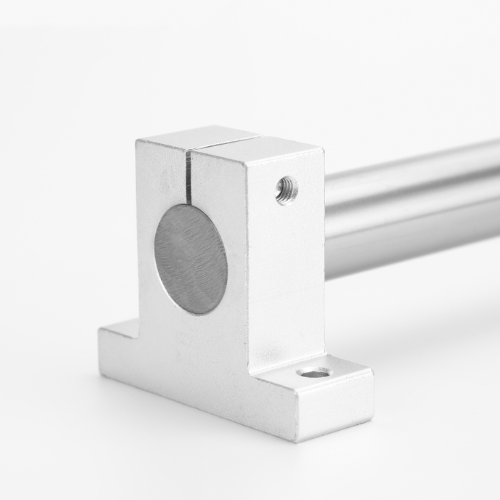

MGW‑H linear guide

Release time:

2025-08-04

The MGW‑H linear guide is a precision linear motion component that plays a vital role in the industrial sector.

1. Structural Features

High-Rigidity Design

The MGW‑H linear guide's unique structural design provides exceptional rigidity. The guide rail's shape and material selection have been carefully optimized to withstand high loads, maintaining stable performance under both vertical pressure and horizontal lateral forces. This characteristic is particularly critical in heavy-duty machining equipment, such as large milling and boring machines, ensuring precise tool positioning during machining without deviation caused by guide rail deformation.

Precision Manufacturing

High-precision machining techniques are employed during the manufacturing process. The guide rail's surface flatness and straightness are achieved to extremely high standards. The precise fit between the guide rail's rolling elements and raceways effectively minimizes backlash during movement. This enables the slider to achieve micron-level precision motion on the guide rail, meeting the demands of industries with extremely high precision requirements, such as semiconductor manufacturing equipment and precision optical instruments.

2. Performance Advantages

Low Friction Coefficient

The MGW‑H linear guide's rolling friction method significantly reduces friction. Compared to traditional sliding guides, the low coefficient of friction means lower energy loss, reducing the power requirements of equipment during operation. This not only saves energy but also extends the service life of the equipment, as lower friction generates less heat and reduces wear on the guide rails and slides.

High Speed and High Acceleration

Due to its low friction and precise structure, the MGW‑H linear guide enables linear motion at high speeds and accelerations. In automated production lines, such as high-speed sorting equipment and the articulation of robotic arms, this linear guide ensures fast and accurate operation, improving production efficiency.

3. Application Areas

Machine Tool Industry

In lathes, grinders, and other machine tools, the MGW‑H linear guide provides precise guidance for the relative motion of tool and workpiece. This improves machining accuracy and surface quality, meeting the ever-increasing demand for component machining precision.

Automated Equipment

For automated warehousing and logistics equipment such as stackers and automated guided vehicles (AGVs), linear guides ensure smooth and precise cargo handling. In industrial robotics, they are key components for the flexible and precise movement of robotic arms.

Electronics Manufacturing Equipment

In electronic chip manufacturing equipment and circuit board placement equipment, the high precision and low friction of the MGW‑H linear guide facilitate the precise assembly and processing of tiny electronic components, ensuring the quality and performance of electronic products.

Latest information

2025-08-04