MGW-C/MGW-H

Category:

Linear guide

Key words:

Linear guide

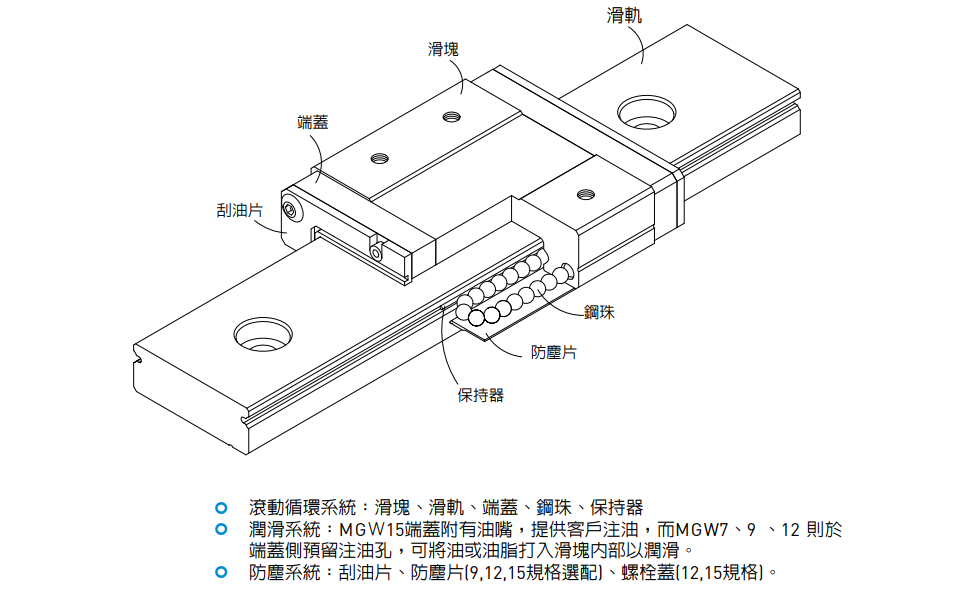

MGWFeatures of Small Wide Linear Slide

1. The design of the widened slide rail greatly improves the moment load capacity and can be used in single shaft.

2. Gothic type four point contact design, can withstand the load in various directions and has the characteristics of high rigidity.

3. The slider is equipped with micro-small retaining steel wire, and the steel ball of the slider will not fall off.

4. Slide rail, slider and all metal fittings are made of stainless steel, with anti-corrosion characteristics.

Amidst the rapid growth of industrial automation, the MGW‑H linear guide stands out for its superior performance, making it an ideal choice for numerous mechanical equipment.

Precise Guidance, Smooth Operation

The MGW‑H linear guide offers exceptional guiding accuracy. Its unique guide rail design, coupled with a high-precision ball or roller recirculation system, ensures smooth, stable linear motion of the slide along the rail. Even during high-speed operation, motion errors are kept to a minimum, providing precise guidance for various mechanical equipment, ensuring machining and operational accuracy and effectively improving product quality.

High Load Capacity, Durability

This linear guide boasts a strong load-bearing capacity. Its use of high-quality steel and advanced heat treatment processes ensures the rail and slide possess exceptional hardness and strength. Whether it's vertical gravity loads or horizontal lateral forces, the MGW‑H linear guide can easily withstand them. Even under long-term, high-load operating conditions, it maintains stable performance, significantly extending the life of the equipment and reducing maintenance costs and downtime.

Low Friction, Energy-Saving and High-Efficiency

The MGW‑H linear guide features an optimized contact design between the balls or rollers and the guide rail, effectively reducing friction. This low friction not only makes the slider move more easily on the guide rail, reducing energy loss and achieving energy savings, but also reduces wear between the guide rail and slider, further extending the guide's service life. Furthermore, the smooth movement created by low friction helps reduce noise during operation and improves the working environment.

Easy Installation and Strong Compatibility

This linear guide is designed with ease of installation in mind. Its standardized mounting dimensions and interfaces make it easily compatible with a wide range of mechanical equipment. Whether installing new equipment or upgrading existing equipment, the MGW‑H linear guide can be installed quickly and accurately, saving users valuable time and effort.

With its precise guidance, high load capacity, low friction, and easy installation, the MGW‑H linear guide provides a strong guarantee for efficient and stable operation in industrial production.

Related Products

Online message