(HJ Series) Toothless

Category:

Slewing ring bearing

Key words:

Slewing ring bearing

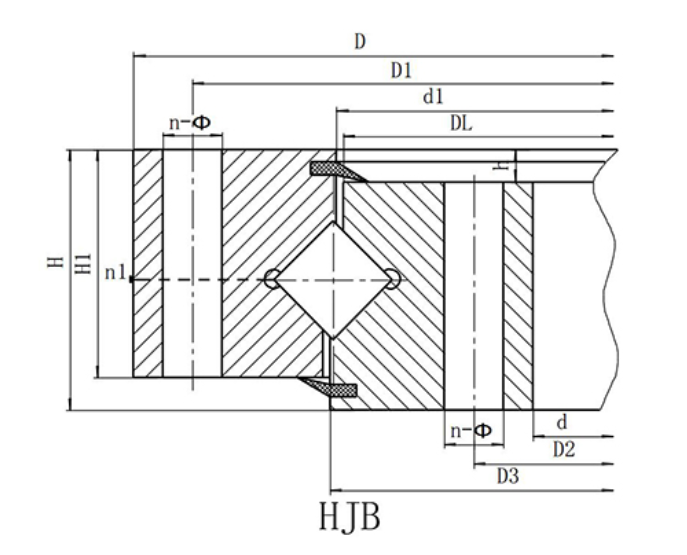

(HJ Series) Single-row Cross Roller Slewing Bearing-Toothless

Structural characteristics, performance and scope of application

The single-row cross-roller slewing bearing is composed of two seat rings. It has compact structure, light weight, high manufacturing accuracy, small assembly gap, and high installation accuracy. The rollers are arranged in a 1:1 cross and can bear at the same time. Axial force, tilting moment and large radial force are widely used in lifting and transportation, engineering machinery and military products.

| Serial Number | toothless type DL mm |

Exterior dimension | Mounting dimensions | Structure size | Reference Weight kg |

|||||||||

| D mm |

d mm |

H mm |

D1 mm |

D2 mm |

n | mm | n1 mm |

D3 mm |

d1 mm |

H1 mm |

h mm |

|||

| 1 | HJB.20.625 | 725 | 525 | 80 | 685 | 565 | 18 | 18 | 3 | 627 | 623 | 68 | 12 | 100 |

| 2 | HJB.20.720 | 820 | 620 | 80 | 780 | 660 | 18 | 18 | 3 | 722 | 718 | 68 | 12 | 120 |

| 3 | HJB.30.820 | 940 | 705 | 95 | 893 | 749 | 24 | 20 | 4 | 822 | 818 | 83 | 12 | 210 |

| 4 | HJB.30.880 | 1000 | 760 | 95 | 956 | 800 | 24 | 20 | 4 | 882 | 878 | 83 | 12 | 230 |

| 5 | HJB.30.1020 | 1170 | 875 | 95 | 1120 | 930 | 24 | 22 | 4 | 1022 | 1018 | 80 | 15 | 300 |

| 6 | HJB.36.1220 | 1365 | 1075 | 120 | 1310 | 1130 | 36 | 24 | 6 | 1222 | 1218 | 105 | 15 | 450 |

| 7 | HJB.36.1250 | 1400 | 1090 | 120 | 1350 | 1150 | 36 | 26 | 6 | 1252 | 1248 | 105 | 15 | 520 |

| 8 | HJB.36.1435 | 1595 | 1278 | 120 | 1535 | 1335 | 36 | 26 | 6 | 1437 | 1433 | 105 | 15 | 610 |

| 9 | HJB.45.1540 | 1720 | 1360 | 140 | 1660 | 1420 | 42 | 26 | 6 | 1543 | 1537 | 122 | 18 | 732 |

| 10 | HJB.45.1700 | 1875 | 1525 | 140 | 1815 | 1585 | 42 | 29 | 6 | 1703 | 1697 | 122 | 18 | 844 |

| 11 | HJB.45.1880 | 2100 | 1665 | 160 | 2030 | 1740 | 48 | 32 | 6 | 1883 | 1876 | 140 | 20 | 1400 |

| 12 | HJB.45.2115 | 2325 | 1900 | 160 | 2245 | 1980 | 48 | 32 | 6 | 2118 | 2112 | 140 | 20 | 1600 |

| 13 | HJB.45.2370 | 2600 | 2146 | 180 | 2520 | 2220 | 48 | 32 | 6 | 2373 | 2367 | 158 | 22 | 2100 |

| 14 | HJB.45.2600 | 2835 | 2365 | 180 | 2750 | 2450 | 54 | 36 | 6 | 2603 | 2597 | 158 | 22 | 2400 |

| 15 | HJB.50.2820 | 3085 | 2555 | 200 | 3000 | 2640 | 54 | 36 | 6 | 2823 | 2817 | 178 | 22 | 3400 |

| 16 | HJB.50.3120 | 3400 | 2840 | 200 | 3310 | 2930 | 54 | 36 | 6 | 3123 | 3117 | 178 | 22 | 4000 |

| 17 | HJB.50.3580 | 3920 | 3240 | 240 | 3820 | 3340 | 60 | 40 | 6 | 3583 | 3577 | 218 | 22 | 6700 |

| 18 | HJB.50.4030 | 4370 | 3690 | 240 | 4270 | 3790 | 66 | 40 | 6 | 4033 | 4027 | 218 | 22 | 7700 |

| 19 | HJB.50.4540 | 4860 | 4210 | 240 | 4760 | 4310 | 72 | 40 | 6 | 4543 | 4537 | 218 | 22 | 8760 |

Note:

1. n1 is the number of lubricating oil holes, evenly distributed: oil cup M10 × 1 JB/T7940.1-JB/T7940.2.

2. Installation hole n-Φ can be replaced by screw hole; Tooth width B can be changed to H-h.

Related Products

Online message